In the realm of power electronics, the pursuit of efficiency is paramount. As Henry Ford once said, “The only real mistake is the one from which we learn nothing.” In the world of power electronics design, learning from past mistakes and constantly striving for greater efficiency is the key to success. This article will delve into the strategies and techniques for maximizing efficiency in power electronics design, exploring the importance of component selection, circuit topologies, and control techniques.

Choosing the Right Components: The Foundation of Efficiency

When it comes to maximizing efficiency, selecting the right components is crucial. Each component plays a vital role in determining the overall efficiency of the system. Let’s explore some key components and considerations:

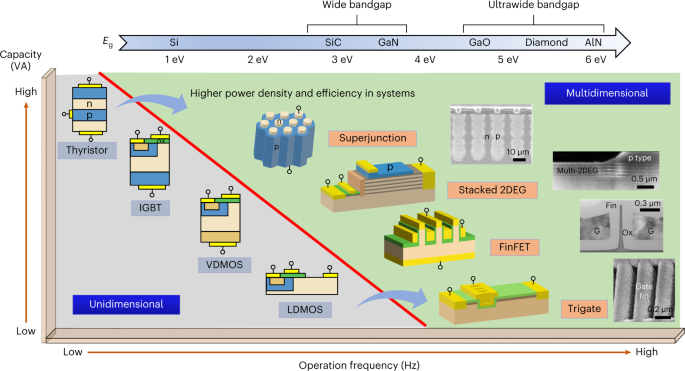

1. Power Semiconductors: Power semiconductors, such as MOSFETs, IGBTs, and SiC/ GaN devices, are at the heart of power electronics circuits. These devices have different characteristics and performance trade-offs. Selecting the appropriate power semiconductor for the specific application is essential for achieving high efficiency.

2. Passive Components: Passive components like capacitors and inductors also impact efficiency. Choosing components with low equivalent series resistance (ESR) and equivalent series inductance (ESL) can minimize losses and improve efficiency.

3. Transformers and Inductors: The design and selection of transformers and inductors are critical for achieving high efficiency in power converters. Factors such as core material, winding design, and magnetic coupling must be carefully considered.

4. Thermal Management: Efficient heat dissipation is essential to prevent temperature rise, which can degrade the performance and reliability of power electronics systems. Selecting suitable heat sinks, thermal interface materials, and cooling techniques is crucial for maintaining optimal efficiency.

Optimizing Circuit Topologies: Efficiency through Design

The choice of circuit topology is another crucial factor in maximizing efficiency. Different topologies have varying efficiency characteristics. Let’s explore some commonly used topologies:

1. Buck Converters: Buck converters are widely used for voltage step-down applications. They offer high efficiency due to their ability to reduce voltage and current stress on the components.

2. Boost Converters: Boost converters step up the voltage and find applications in power factor correction (PFC) circuits. The efficiency of boost converters can be improved through advanced control techniques and component selection.

3. Flyback Converters: Flyback converters are popular for isolated power supply applications. Their efficiency can be enhanced by utilizing synchronous rectification and optimizing transformer design.

4. Resonant Converters: Resonant converters, such as LLC and ZVS converters, utilize resonant tank circuits to reduce switching losses. These converters offer high efficiency by minimizing switching losses and achieving soft switching.

Advanced Control Techniques: Enhancing Efficiency through Control

The control techniques employed in power electronics systems significantly impact efficiency. Effective control techniques help optimize the performance of power converters. Here are some notable control techniques:

1. Pulse Width Modulation (PWM): PWM is widely used in power electronics to control the power delivered to the load. By varying the duty cycle of the switching signal, the average power delivered can be regulated, leading to improved efficiency.

2. Maximum Power Point Tracking (MPPT): MPPT techniques are crucial in photovoltaic systems, where they track the maximum power point of the solar panel. Optimizing power extraction from the solar panel enhances overall system efficiency.

3. Adaptive Control: Adaptive control techniques dynamically adjust the control parameters based on the operating conditions. These techniques can improve efficiency by adapting to changes in load and input voltage.

4. Digital Control: Digital control techniques offer precise control and flexibility. They allow for advanced control algorithms, parameter adjustments, and fault diagnostics, resulting in improved efficiency and performance.

Conclusion: An Ongoing Quest for Efficiency

Efficiency in power electronics design is not a destination but an ongoing journey. As technology advances and new challenges emerge, engineers must continuously strive for greater efficiency in their designs. The selection of high-quality components, optimization of circuit topologies, and implementation of advanced control techniques are crucial steps in achieving optimal efficiency. In the words of Thomas Edison, “There is always a way to do it better… find it.” By embracing this mindset and pushing the boundaries of power electronics design, we can unlock new levels of efficiency and shape a more energy-efficient future.