In electronics manufacturing, soldering creates mechanical and electrical connections critical for functionality and longevity. However, achieving truly robust solder joints demands a holistic approach spanning materials, design, process controls, inspection, and training. Common weaknesses like cold joints, voids, cracks, or insufficient wetting can degrade performance and reliability over time. By exploring the metallurgy, methods, tools, and human factors influencing solder joint quality, we can understand the best practices for consistent, defect-free joining.

The Metallurgy of Soldering

Soldering success hinges on metallurgical principles concerning surface wetting, oxide formation, intermetallic diffusion, and more. Solder alloys like the near-eutectic 63Sn/37Pb blend are engineered to melt and flow at relatively low temperatures while resisting electromigration. Certain alloying elements improve solder properties like wetting or creep resistance for different applications.

Matching solder chemistry with the metallizations on component leads and pads ensures proper interfacial reactions. Pb-free solders like SAC alloys leverage additions of silver and copper to wet copper pads effectively. Such fundamental material compatibilities must be verified to build reliability. As Athena Manufacturing’s Matt Kelly notes, “Getting the basics like metal pairs right avoids unnecessary defects.” Proper pre-tinning also prevents oxidization that impedes wetting.

Once flowed, the solder rapidly cools to form a crystalline joint. The microstructure should solidify free of voids with adequate grain refinement for strength and crack resistance. Extended cooling can coarsen crystals, reducing mechanical integrity. Designs must enable sufficient thermal dissipation to form orderly joint structures. Various alloy modifications like adding trace elements of nickel, antimony, or bismuth help tailor microstructures and properties for different temperature profiles or stress levels.

In service, solder joints experience thermo-mechanical stresses. Intermetallic regions are prone to fracture over cyclic strain. However, bonds can be adapted through alloys or underfills to withstand harsh conditions in automotive, aerospace, oil and gas, or other extreme environments. Overall, fundamentals underpinning solder chemistry, microstructures, mechanics, and reliability remain active research areas.

Process Controls for Repeatability

Assuring robust soldering also requires controlling the joining process. Automation establishes repeatability across operator skill levels. For example, selective soldering machines use precise pumps and nozzles to target joints. Fountain designs eliminate variability in flux volume and exposure. Parameters like preheat and contact time can also be programmed consistently.

Monitoring thermal profiles during reflow soldering helps identify process deviations. Data loggers or thermocouples chart temperature gradients to ensure uniform heating within acceptable ranges. Delta-T measurements confirm leads warm evenly to avoid board or component damage. Such analytics enhance quality management.

However, Hand soldering still suits low volume or rework applications. Tools like solder tip temperature controls, hands-free fume extractors, and illuminated magnifying lenses aid precision and ergonomics. Techniques like drag soldering alternated between sides equalizes heating distribution. Repeatable hand soldering relies on adaptable fixtures and well-designed workflows. Automated optical inspection can verify hand assembly quality.

Inspection Techniques for Defect Detection

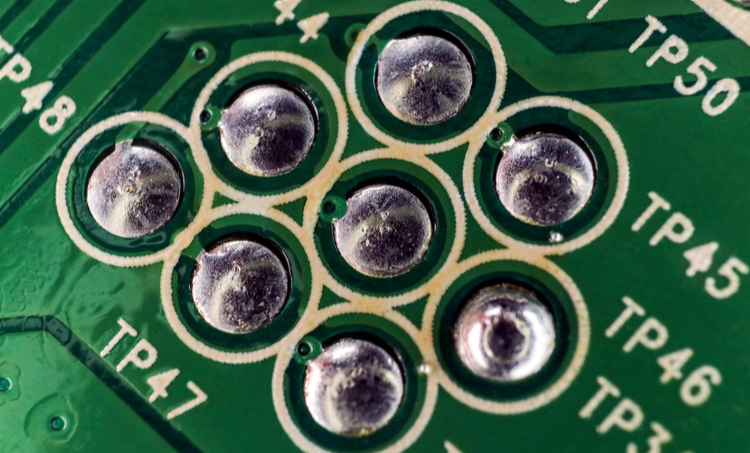

Thorough inspection and testing safeguard against latent soldering defects slipping through. Automated optical inspection (AOI) systems capture high-resolution images of assemblies, using algorithms to flag common anomalies like missing joints, insufficient fillets, or lifted pads. AOI proves highly effective for finding surface flaws inline. However, internal faults require other techniques.

X-ray imaging offers non-destructive internal inspection. Voids, cracks, and hidden defects become clearly visible. For example, Nikon’s X-ray systems examine LED assemblies, checking solder bump bonds between densely packaged chips. Such inspection tools help quantify risks before products ship.

For quantitative integrity assessment, flash thermography analyzes thermal signatures. Abnormalities conduct heat slower, causing detectable hotspots during thermal stimulation. This method also assesses issues below BGAs. Combined inspection approaches thereby assure sound solder joints throughout complex electronics.

Training and Certifications Build Workers’ Skills

Ultimately, skilled operators drive process quality. Training programs like IPC J-STD certification teach best practices for soldering and inspection. Ongoing education communicates evolving techniques as electronics advance. Operators gain nuanced understanding of how individual actions influence solder joint formation across component types.

For companies, structured training ensures employees use proper methods consistently. Certifications also provide workmanship documentation for clients. IPC standards like 610 for acceptability and 7711 for rework qualifications are industry references that build expertise. Coupled withSix Sigma and lean manufacturing disciplines, training sustains improvements. Assemblers develop both artful proficiency and scientific discipline for excellence.

In summary, holistic soldering mastery demands technical, process, and human stacking. Precision across materials, equipment, and personnel establish repeatability and longevity. When underlying metallurgical principles align with controlled automation and worker craftsmanship, robust electronics joining is assured.