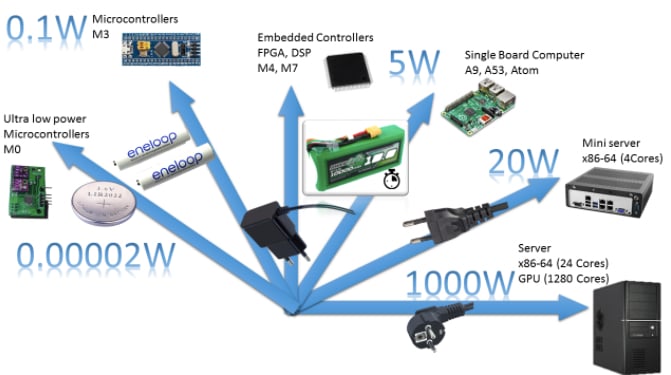

Low-power microcontrollers (MCUs) are critical for Internet of Things edge devices operating on batteries or energy harvesting. Advanced MCUs balance processing performance with minimal energy consumption. Key factors to compare when selecting IoT MCUs include architecture, functionality, and efficiency.

Evaluating Computational Performance

Performance requirements depend on target applications. Simple sensors may only need basic MCUs running at tens of MHz. More complex applications like building automation or asset tracking demand faster processors above 100 MHz along with hardware acceleration blocks.

Leading MCUs offer CPU options spanning from Arm Cortex-M0 to M4 designs fabricated down to 40nm. Benchmarking exact DMIPS helps match computational power to application needs.

“We select MCUs based on CPU performance projections for our IoT analytics algorithms,” noted Sarah Wu, Principal Engineer at Samsara.

Assessing Functional Integration

Higher integration allows eliminating external components to reduce costs and board space. Key peripherals like analog-to-digital converters (ADCs), serial interfaces, and encryption blocks may be integrated on-chip.

For example, the Microchip ATSAM4SD32C integrates ADCs, touch sensing, USB, and cryptographic accelerators. Tight integration optimizes data flows and signaling while minimizing external devices.

“We leverage MCU integration to condense our IoT endpoint hardware designs,” explained John Forecast, Engineering Director at Analog Devices.

Optimizing Power Efficiency

Minimizing power consumption is imperative for battery-operated edge devices. MCUs leverage strategies like dynamic voltage and frequency scaling, clock gating, and optimized pipelining to conserve power.

Lower voltage operation down to 1V saves power. Some MCUs enter sleep modes drawing just nanoamps between tasks. And hardware accelerators avoid inefficient software processing. Comparing benchmarks like CoreMark/mW provides efficiency insights.

“We select MCUs based on real-world power profiles using tasks from our target applications,” said Monica Chen, Senior Engineer at Sensaura.

Evaluating Low-Power Modes

Nearly all IoT devices spend extensive time in low-power sleep states. Different MCUs offer various sleep and shutdown modes balancing power savings with wakeup latency and peripherals kept active.

For example, STMicro’s STM32L4 MCUs provide six graduated stop modes down to 640nA at 1.71V. Flexible peripheral management during sleep allows customizing for specific IoT workloads.

As STMicro’s Jacopo Pagano noted, “Sophisticated power modes are crucial to extend battery lifetimes from months up to a decade.”

Assessing Physical Interfaces

Interfacing physically with sensors, actuators, and other peripherals is central to IoT edge devices. Different MCUs offer varying on-chip peripherals like analog inputs, specialized serial buses, and control timers.

For example, the Renesas RE01 embeds rich analog interfaces like multiple ADCs, comparators, and op-amps alongside diverse serial connectivity. Tight on-chip integration suits sensor hubs.

“We selected our MCU based on its ability to directly interface with over 20 different environmental sensors for our platform,” said Michelle Kuo, CTO of Losant.

Supporting Security Needs

IoT devices require strong security foundations to counter growing threats. Hardware security features like secure boot, trusted execution environments, and cryptography accelerators safeguard MCU operations.

For example, Microchip’s Trust Platform Architecture provides end-to-end security spanning chip manufacturing through deployed operations. Hardware-enforced protections prevent tampering.

“We leverage MCUs with built-in security to protect our IoT fleet,” said Ray Porras, CTO of Ivanti.

Evaluating Software Ecosystems

The availability of proven software like RTOS, stacks, and libraries accelerates development. Mature MCU families offer extensive code libraries and examples. Vibrant developer communities provide support.

For example, NXP’s LPC MCUs support the MCUXpresso SDK, IDE, and partner ecosystem to simplify prototyping and production. Reusable components boost productivity.

“Leveraging robust MCU software ecosystems cuts our development time by months,” remarked Samir Patel, Director of Software at Omega.

Considering Scalability Needs

If solutions may scale up in complexity, multicore MCU options like Cypress PSoC 6 provide headroom. Similar MCU families offer pin-compatible options spanning capability levels. This enables designing once then scaling up.

For example, NXP Kinetis Kxx MCUs offer 60+ scalable family members. Consistent SDKs ease adapting between models. And hardware compatibility simplifies reusing designs.

“We leverage scalable MCU families to design once then scale to higher capabilities just by substituting an MCU,” said Steve Graves, CTO of Predixion.

In summary, critical MCU selection factors include benchmarked performance, integration, efficiency, interfaces, security, software support, and scalability. Thoroughly evaluating IoT MCUs on these technical measures ensures the best fit for target applications.