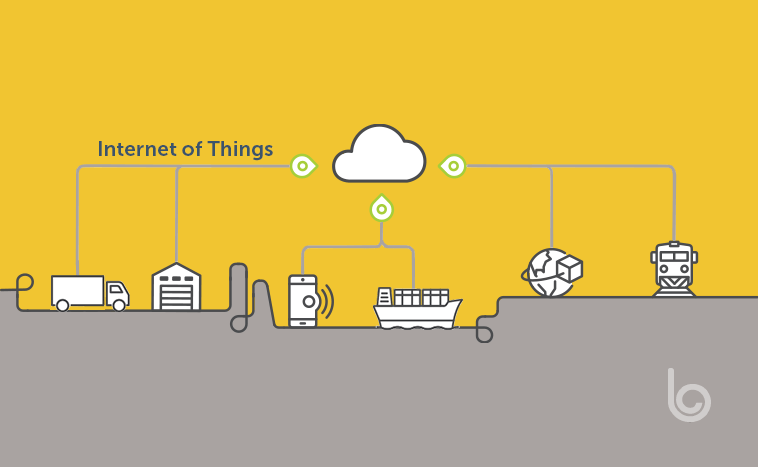

Supply chains are adopting Internet of Things (IoT) sensors for real-time visibility and intelligence. By monitoring key assets, conditions, and processes, IoT data enables faster and smarter supply chain decisions. Sensor-driven agility and automation will be crucial as supply chains face growing complexity and volatility.

Tracking Assets End-to-End

Attaching sensors to supply chain assets provides location and status visibility from production through last-mile delivery. GPS units on containers, trucks, and rail cars track transit. RFID tags monitor warehouse inventory. And sensors measure cargo temperature, humidity, shocks, and tilt.

This end-to-end transparency flags delays and maximizes asset utilization. As Bunnie Huang, CEO of Supplyframe, notes, “Live asset insights are invaluable for managing the physical flow of goods through dispersed global networks.”

Monitoring Product Quality

In-transit sensors also track conditions that may compromise product quality or shelf life. Temperature loggers identify if perishable items spoiled in overheated trucks. Accelerometers detect mishandling. Gas sensors reveal food spoilage. And LiDARs measure box crushing that can damage contents.

Catching quality issues early prevents wasteful deliveries and returns. “Real-time remote quality monitoring is a game-changer for supply chains moving fragile or perishable goods,” commented Ariel Ezrachi, Oxford University Professor of Competition Law.

Boosting Warehouse Efficiency

Within warehouses, IoT solutions like smart racks, robotic vehicles, and wearables boost accuracy and speed. Sensors assist pickers, verify inventory, optimize routes, and monitor forklift impacts.

This constant data flow allows warehouses to automate safely. Activity analytics identify bottlenecks. And edge processing avoids IT system latency. “IoT technologies are enabling warehouse productivity gains of 20% or more,” noted Gideon Brothers CEO Matej Gideon.

Improving Factory Agility

Connected factory equipment provides data to optimize manufacturing operations. Status monitors predict maintenance needs. Sensors detect defects and bottlenecks. Energy meters identify savings opportunities. And data layers feed advanced analytics.

Thisfactory-floor visibility facilitates agile responses to disruptions and shifting customer demands. “Sensor-driven manufacturing transparency allows our factories to adapt faster and smarter,” explained Karen Murphy, Chief Digital Technology Officer at Microsoft.

Securing Critical Infrastructure

Intrusion detection systems monitor facilities for security breaches using lidar, infrared, sound, and vibration analytics. Video surveillance and access controls further safeguard infrastructure. And tamper-evident packaging protects high-value cargo.

Proactively addressing vulnerabilities reduces supply chain risk. “IoT security technologies secure global transportation networks against emerging threats,” remarked National Governor’s Association Director William Barnes.

Preventing Counterfeiting

Anti-counterfeiting sensors verify legitimate products using serial numbers, nano-encryption, microtaggants, and chemical signatures. Every scan accumulates data on cloned and diverted products to combat counterfeiters and grey market abuses.

Brand protection preserves hard-won customer trust. “IoT product authentication solutions are crucial for eliminating counterfeits that undermine brand equity,” stated Wayne Leung, CEO of CryptoFights.

Automating Compliance

Sensors streamline regulatory compliance by continually logging required data like temperatures for food and pharmaceuticals. Automated reporting validates procedural adherence. And remote audits reduce inspection costs.

“Automating compliance data collection with IoT sensors provides assurance while limiting overhead,” explained Kristin Russell, Global Supply Chain Compliance Lead at Abbott Laboratories.

Utilizing Predictive Analytics

Looking forward, advanced analytics will transform IoT sensor data into prescriptive insights. By analyzing thousands of supply chain variables, artificial intelligence can anticipate disruptions, mitigate risks, and guide optimal decision making.

“The future of supply chain intelligence relies on predictive analytics to drive proactive resilience and performance,” said MIT Professor David Simchi-Levi.

In summary, IoT sensor solutions deliver comprehensive supply chain transparency, efficiency, and security. The rich data empowers nimble responses to dynamic market conditions. And sophisticated analytics will further optimize future supply networks. Sensor-driven intelligence is becoming imperative for supply chain excellence.