In the world of electronics, effective thermal management is essential for maintaining component reliability and performance. As stated by Bill Gates, “Success is a lousy teacher. It seduces smart people into thinking they can’t lose.” In the realm of thermal management, failure to address heat-related issues can lead to catastrophic consequences. This article explores the principles of thermal management and heatsink design, delving into the importance of heat dissipation, heatsink selection, and optimization techniques.

Understanding Heat Dissipation: The Importance of Thermal Management

Heat dissipation is a critical aspect of electronic design. As electronic devices operate, they generate heat due to resistive losses and power dissipation. Excessive heat can lead to reduced component lifespan, thermal runaway, and even complete system failure. Effective thermal management ensures that the generated heat is efficiently transferred away from sensitive components, maintaining their optimal operating temperatures.

The Role of Heatsinks: Enhancing Heat Dissipation

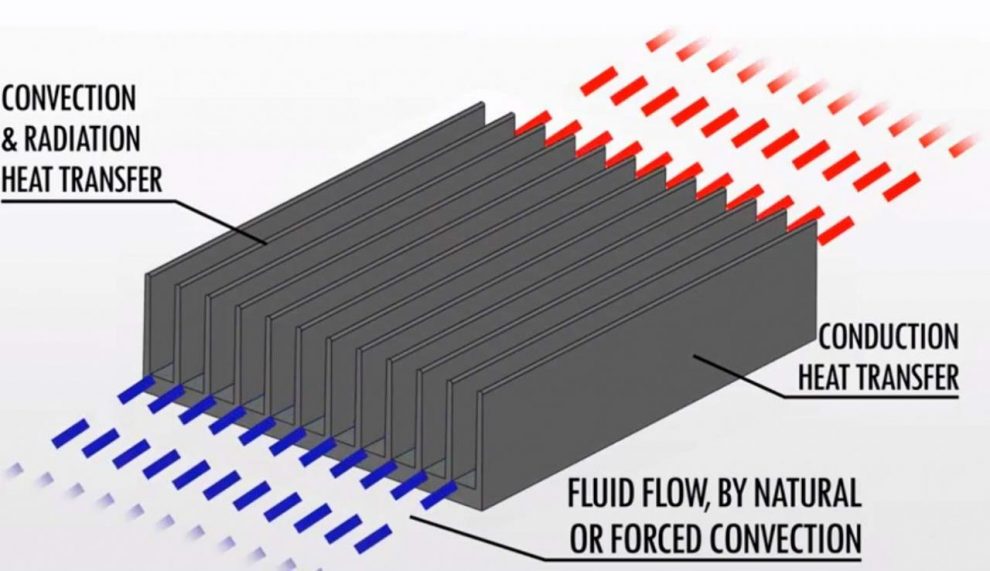

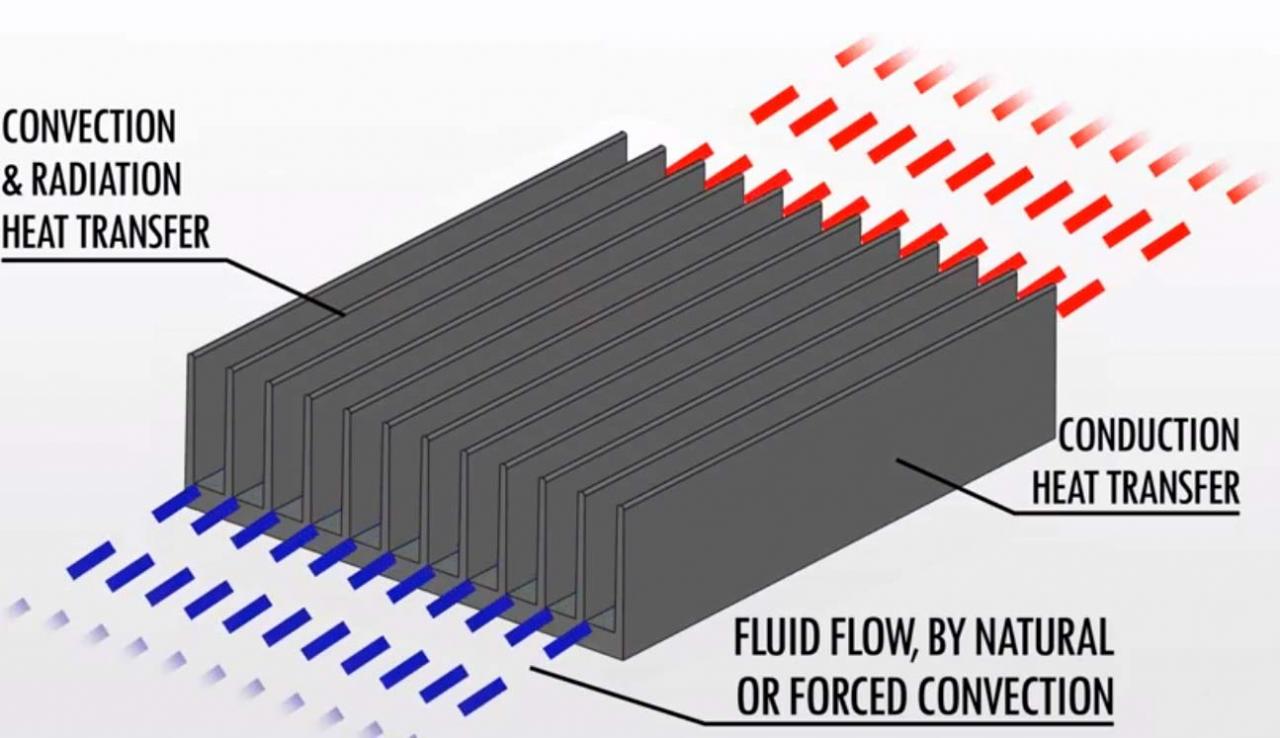

A heatsink is a passive thermal management component designed to absorb and dissipate heat. It provides a larger surface area for heat transfer and promotes convective cooling by increasing airflow. Heatsinks can be found in various electronic systems, including computer CPUs, power electronic devices, LED lighting, and more. Let’s explore the key considerations and design principles for effective heatsink implementation.

1. Heatsink Selection: Matching the Application

Choosing the right heatsink for a specific application is crucial. Heatsinks come in various shapes, sizes, and materials, each with its own thermal conductivity and performance characteristics. Key factors to consider when selecting a heatsink include:

- Thermal conductivity: The ability of the heatsink material to conduct heat efficiently.

- Surface area: A larger surface area allows for better heat dissipation.

- Fin design: The arrangement and size of fins affect the airflow and heat transfer rate.

- Attachment method: The heatsink should be securely attached to the heat-generating component for optimal thermal transfer.

2. Design Considerations: Maximizing Heat Transfer Efficiency

Effective heatsink design involves optimizing heat transfer from the heat source to the surrounding environment. Here are some design principles to enhance heat dissipation:

- Proper positioning: Position the heatsink in close proximity to the heat-generating component to minimize thermal resistance.

- Thermal interface materials: Use high-quality thermal interface materials, such as thermal paste or pads, to ensure efficient thermal contact between the component and the heatsink.

- Fin geometry: Optimize the fin geometry for enhanced convective cooling. Fin spacing, height, and thickness impact the airflow and heat transfer performance.

- Airflow management: Consider the system’s overall airflow, ensuring adequate ventilation and minimizing obstructions around the heatsink.

3. Advanced Heatsink Technologies: Pushing the Boundaries

Advancements in thermal management have led to the development of innovative heatsink technologies. These technologies offer improved heat dissipation capabilities and thermal performance. Let’s explore some notable advancements:

- Heat pipes: Heat pipes are sealed copper tubes filled with a working fluid that transfers heat efficiently through phase change. They are commonly used to transport heat from the heat source to the heatsink.

- Vapor chamber: Vapor chamber technology utilizes a sealed chamber filled with a working fluid that vaporizes and condenses, effectively transferring heat away from the heat source.

- Direct liquid cooling: In some high-power applications, direct liquid cooling systems use liquid coolant to directly absorb heat from the heat-generating components, offering enhanced cooling capabilities.

Conclusion: Cool and Efficient Electronics

Thermal management and heatsink design principles are essential for maintaining the reliability and performance of electronic systems. As technology advances and power densities increase, effective heat dissipation becomes even more critical. By selecting appropriate heatsinks, optimizing heatsink design, and embracing advanced thermal management technologies, we can ensure the cool and efficient operation of our electronics. In the wise words of Steve Jobs, “Design is not just what it looks like and feels like. Design is how it works.” In the world of thermal management, successful design ensures that heat works to dissipate, rather than to hinder, the functionality and reliability of electronic systems.